What We Offer

From Small to Large Scale – 25m³/h to 240m³/h Concrete Plants for Sale.

Available in both Mobile and Stationary, EPDAS Concrete Batching Plants provide precision, efficiency, and durability for any project.

MCBP Mobile Batching Plant

Ready for transfer at any time!

Theoretical productivity: 25-50m3/hr

Mixer model: JS500-JS1000

Feeding mode: Belt type

Mixing motor power: 18.5-37kw

Get A Quote

Theoretical productivity: 25-50m3/hr

Mixer model: JS500-JS1000

Feeding mode: Belt type

Mixing motor power: 18.5-37kw

YHZS Mobile Batching Plant

Modular design & good mobility!

Theoretical productivity: 25-100m3/hr

Mixer model: JS500-JS2000

Feeding mode: Belt type

Mixing motor power: 52-140kw

Get A Quote

Theoretical productivity: 25-100m3/hr

Mixer model: JS500-JS2000

Feeding mode: Belt type

Mixing motor power: 52-140kw

YHZM Mobile Batching Plant

Perfect for compact construction sites!

Theoretical productivity: 25-100m3/hr

Mixer model: JZM500-JZM2000

Feeding mode: Belt type

Mixing motor power: 42-77.5kw

Get A Quote

Theoretical productivity: 25-100m3/hr

Mixer model: JZM500-JZM2000

Feeding mode: Belt type

Mixing motor power: 42-77.5kw

Foundation Free Concrete Plant

Any site, any project!

Theoretical productivity: 60-180m3/hr

Mixer model: JS1000-JS3000

Feeding mode: Belt type

Mixing motor power: 113-200kw

Get A Quote

Theoretical productivity: 60-180m3/hr

Mixer model: JS1000-JS3000

Feeding mode: Belt type

Mixing motor power: 113-200kw

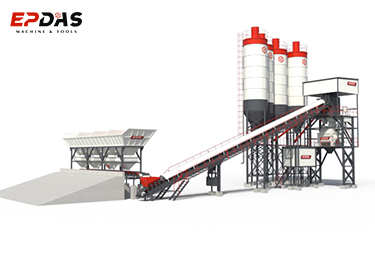

Stationary Concrete Plant

Designed for large-scale projects!

Theoretical productivity: 25-240m3/hr

Mixer model: JS500-JS4000

Feeding mode: Bucket type/Belt type

Mixing motor power: 18.5-150kw

Get A Quote

Theoretical productivity: 25-240m3/hr

Mixer model: JS500-JS4000

Feeding mode: Bucket type/Belt type

Mixing motor power: 18.5-150kw

Dry Mix Concrete Plant

Fully customized plant based on clients' project

Theoretical productivity: 15-180m3/hr

Central mixer: NONE

Feeding mode: Belt type

Fixed or Mobile: Either is acceptable

Get A Quote

Theoretical productivity: 15-180m3/hr

Central mixer: NONE

Feeding mode: Belt type

Fixed or Mobile: Either is acceptable

Smarter & Faster

One Powerful Mixer = Triple the Results!

Our concrete batching plants use advanced concrete mixing technology to reduce production time by up to 40% from precise measurement to rapid mixing, while improving quality and maximizing return on investment!

Who We Are

Specializing in all your concrete production needs

Intelligent mixing, sustainable results, customization! - We offer more than 50 configurations to fit your project specifications, and our environmentally friendly design reduces waste without compromising yield and meets stringent industry standards.

Customized Services

Cost Effective

Technical Support

Various Accessories

Environmentally Friendly

One-year Warranty

We have more than

40 years experience in Concrete Machinery.

40 years experience in Concrete Machinery.

Mega-Scale Production, Cutting-Edge Tech!

Located in Shandong, China, EPDAS covers an area of 780,000 square meters and has 380 employees and 7 experts responsible for product research and development, manufacturing and global market services.

Speak with a Specialist

Why Choose Us

Trusted Concrete Batching Plant Manufacturer Since 1978!

We are committed to providing durable, high output concrete batch plant designed to meet a wide range of global customer needs and provide efficient mixing solutions for global construction needs. Request your customized concrete plant today!

End-to-End Service Solutions

- Pre-sales will conduct needs analysis

- During the sale, we will go in and supervise the installation

- After-sales will provide maintenance service

24/7 Expert Support

- Multilingual technical and sales teams on standby

- Instant response via WhatsApp/Email/Phone

- Project specific consultation

Fast Global Shipping

- Pre-vetted logistics partners (DHL/FedEx certified)

- Strategic warehouse hubs in 3 continents

- Customs clearance assistance

Testimonials

What They’re Saying

We have won the recognition and trust of customers with excellent product performance, advanced technology and good reputation.

Successful Cases

EPDAS Powers Construction Worldwide – Our Various Types of Concrete Batching Plants Operate in 168 Countries!

F. A. Q

Frequently Asked Questions

If you have more questions , please contact us immediately. Our professional customer service team can answer your questions and give you the best solution.

-

Dry Mix Concrete Plant Vs. Traditonal Concrete Plant: How To Choose?1. The dry mix plant only batches materials but does not mix them. Users generally use tank trucks to mix concrete; 2. The dry concrete mixing plant is a completely customized equipment. There is no standard model and configuration. It can be customized according to the customer's production requirements; 3. The control system of the dry mix batching plant is more inclined to manual control or semi-automatic control, while the concrete batching plant is more inclined to fully automatic control; 4. The structural design of the dry material station is simple and modular; 5. The requirements of the dry material station for the site foundation are relatively simple.

-

Which kind of your concrete batch plant sells best?We have different types of batching plants, among which fixed plant HZS90, foundation-free concrete plant MHZS120, mobile batch plants MCBP35, YHZM35, YHZS100 have the best sales volume.

-

YHZS vs MCBP Mobile Batching Plant: How to choose?- YHZS mobile concrete mixing station has a full range of models, covering 25-100m³/h mainstream production, more accurate measurement than MCBP, unloading height of 3.8 meters, and mixer trucks can enter and exit normally. - MCBP small mobile mixing station can truly realize mobile convenience, only one trailer is needed, and users can transfer the mixing station at any time; delivery only requires 1 40HQ transportation, saving freight and customs clearance costs!

-

What should I consider before buying a concrete plant?1. Clarify the hourly/daily production requirements, and it is recommended to choose a model that is 20% higher than the current demand. 2. Evaluate the construction period. For short-term projects, you can choose a mobile type, and for long-term high-volume production, you can choose a fixed type. 3. Clarify the site and environmental requirements, check the power and drainage systems, and choose an environmentally compliant batching plant.

-

What if I don't know how to install and use the batching plant?Our engineers will personally go to your site to complete the installation and precision debugging of the mixing plant to ensure that the equipment reaches the best operating condition. We will also provide hands-on operation training to workers, including the switching process, daily maintenance specifications, etc.; later on, there will be free upgrade reminders to notify you of applicable software updates or energy-saving transformation programs at the first time.

-

How does a mobile concrete batch plant work?The mobile concrete batching plant uses precise batching and mixing technology to mix raw materials such as aggregates, cement, water, and additives evenly to produce uniform concrete, which is then sent to the construction site for pouring.